Return labels of the future may be invisible

Dansk Retursystem is among the participants in HolyGrail2.0, which is an international collaboration with the European Brand Association, AIM towards a new cutting-edge technology for sorting packaging waste.

Information

Artikel

In Denmark we have one of the world’s best deposit systems, where as much as 92% of all empty bottles and cans with a deposit label are returned and turned into new ones. However, if we are to include the remaining 8%, the Holy Grail – in the shape of a digital watermark on all packaging – can be the lever to channelling some of the bottles and cans that would otherwise end up in the waste streams into a closed loop where they are recycled ‘bottle-to-bottle’.

When a group of companies, led by the European Brand Association, AIM, recently broke the news about HolyGrail2.0 – a new technology for sorting packaging waste – Dansk Retursystem was among the participants. Because, even though in Denmark we have one of the world’s best deposit systems, with a substantial 92% return, we would still like to catch the last 8%. And maybe technology can help us with that. The results from previous Dansk Retursystem research show that the vast majority of the 8% that is not returned ends up in waste streams, either from private household waste, commercial waste or public litter bins. If, with new technology, we succeed in getting bottles and cans out of waste streams and into a bottle-to-bottle loop, it will benefit our climate, our environment and the earth’s resources.

Deposits are more than money

For plastic bottles to be recycled in a ‘bottle-to-bottle loop’, we need to be able to collect packaging waste of uniform quality. This also requires cooperation with specialised recycling companies and a demand for the recycled materials among packaging manufacturers. And that is what the Danish deposit system can provide and why deposits are so much more than the money you get for returning your empty bottles and cans. They are a guarantee that the bottles and cans will be recycled into new ones. Very little is wasted in the process and the materials can, in principle, be recycled endlessly, so long as they stay in the closed loop. Because of the high demands on the quality of food packaging, a plastic bottle that has been recycled into a fleece sweater or an aluminium can that has been used for a bicycle frame, cannot be turned back into a bottle or a can, and are consequently out of the closed loop. For a country like Denmark, where there is a well-functioning deposit system to ensure a closed loop and a high quality of recycling, this is not sustainable.

100% circularity

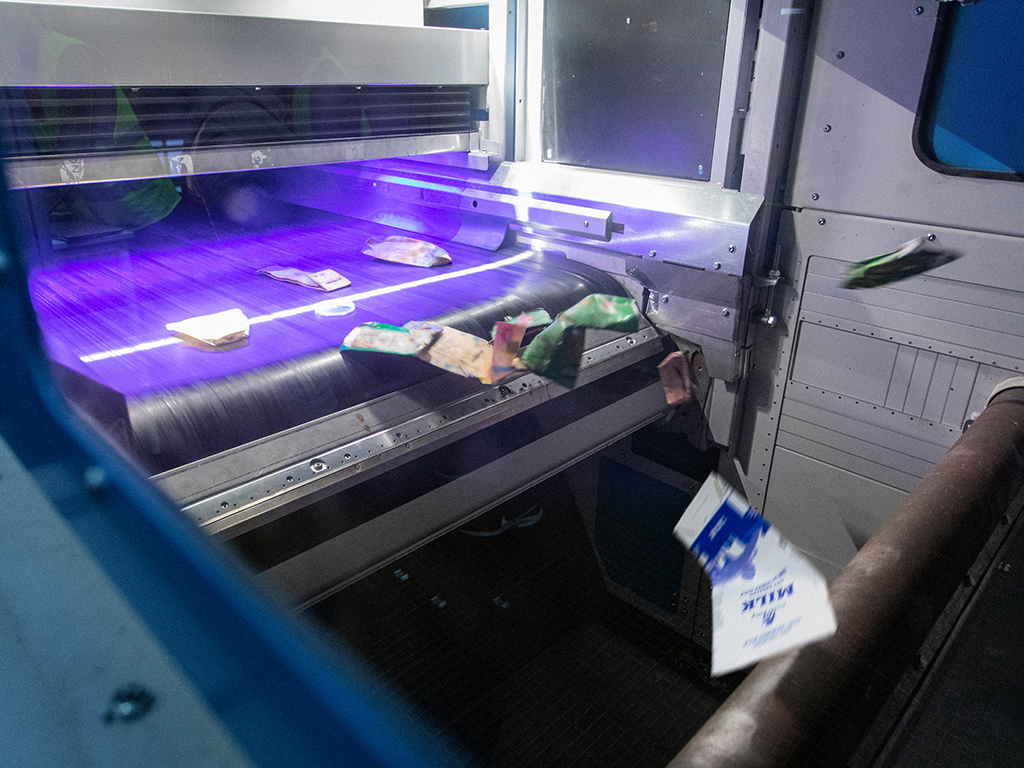

In Dansk Retursystem it is our goal that 99% of all bottles and cans with a deposit label are returned and recycled. This is an ambitious goal, because not only do we need 99% returned, we also need to recycle 99% of the materials. Nothing can be lost on the journey, from the collection in stores, to the sorting in our factories, and to the melting down at the processers. Even though the recycling rate is high, we are not there yet. Today, for example, 90% of our transparent and light blue plastics are processed into new bottles, and most recently we have managed to include a percentage of green plastic waste in our ‘bottle-to-bottle loop’. We already have an efficient process, and with new technology and increasing demand from the market for recycled plastics we can get closer to our target of achieving 100% circularity for our deposit system.

New technology could make our dreams come true

For consumers, the technology in HolyGrail2.0 can also offer new opportunities. Today, packaging is covered in labels with all sorts of information. Imagine if it could all be gathered in an invisible watermark, allowing consumers to scan the product and get all the information via an app. This could also apply to the deposit label with information about the packaging’s recycling options and the amount of recycled material used in the packaging. We are following this development closely and would like to contribute to it so that with innovation and new technologies we can make it even easier for consumers to get rid of their used bottles and cans in the most sustainable way.

Today, there are many labels and a lot of information on packaging – imagine if it could all be gathered in the invisible watermark